Clean Room Assembly

BT Laser provides clean room production and packaging. Optical, semiconductor, aerospace, and defense industries rely on us to build and deliver dynamic, scalable, manufacturing capacity. Our team is here to help you deliver superior quality products and successful projects.

Important clean room features:

- Deionized water

- Passivation

- Laminar flow hoods

- N2 purge and dry

- Hot N2 and air vacuum seal packaging with N2 back purge

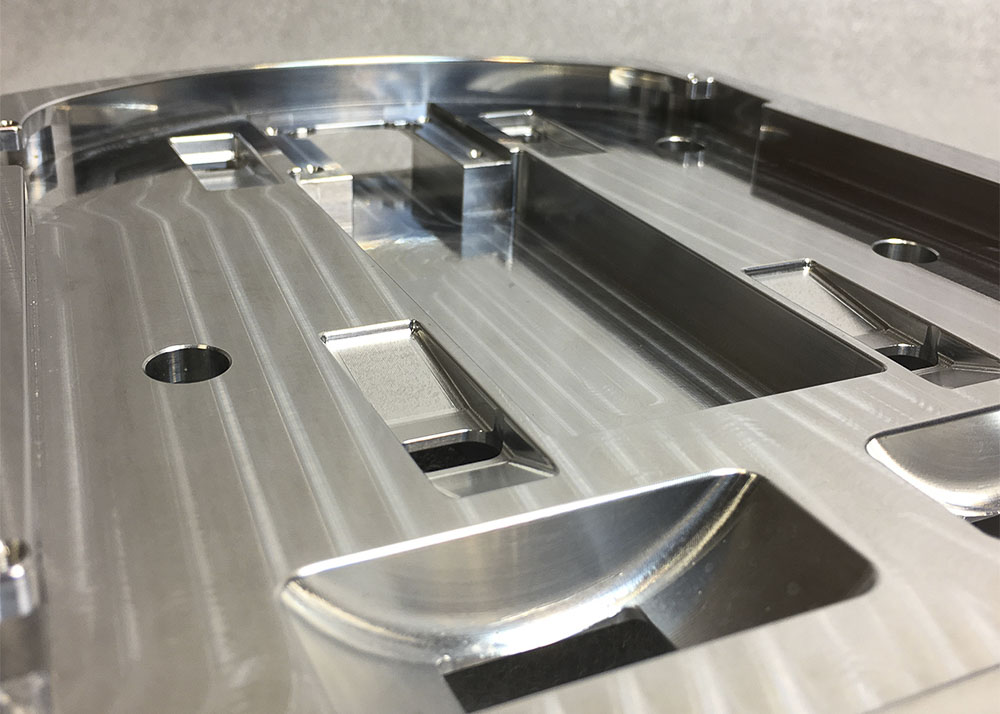

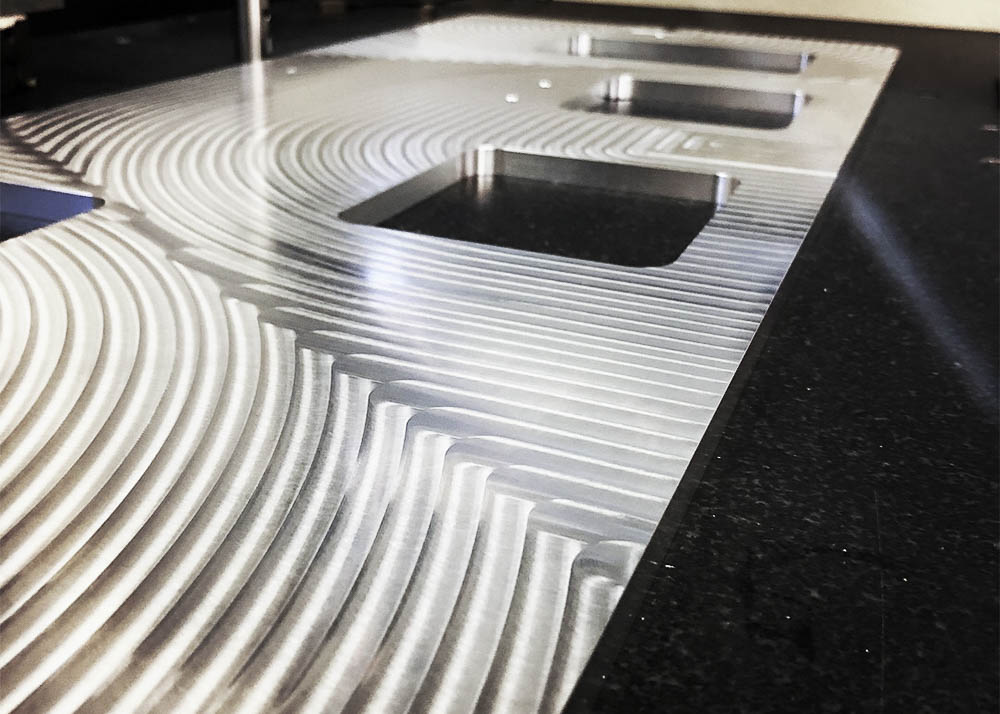

These are the types of products assembled in our clean room

Quality Inspection Equipment

ZEISS CONTURA G2

Capabilities:

- ZEISS VAST XXT TL3 on ZEISS RDS scanning and multiple-point sensor ZEISS XDT TL3: multiple-point sensor Scanning measuring rate up to 500 points/s.

- Stylus length with module: TL3 = 30-150 mm

- maximum stylus weight = 15 g

- TL3 maximum sensor extension = 100 mm

- minimum stylus tip diameter = 0.3 mm

ZEISS CONTURA

Capabilities:

- Active scanning and multipoint sensor.

- Scanning measuring rate up to 500 points/s.

- Variable measuring force (50-1000 mN) for data acquisition.

ZEISS CONTURA RDS

Capabilities:

- Dynamic ZEISS RDS articulating unit for optical and contact sensors.

- Front-to-back and lateral tilt range of ±180°

- Large measuring range

- Rotation increments of 2.5°

- CAA correction for automatic qualification of all 20.736 angular positions for scanning sensors (ZEISS VAST XXT TL3) and multiple-point sensors (ZEISS XDT TL3).

MICROVU VETEX V330

Capabilities:

Optical comparatorSTARRETT HB 350

Capabilities:

Optical comparator

Our Core Manufacturing Services

27 YEARS OF EXPERIENCE & SERVICE

BT Laser is the manufacturing parter you can depend on for reliable lead time and relentless quality control. We can solve nearly any fabrication challenge. Get in touch with us.